Coal columnar activated carbon

In terms of raw materials, columnar activated carbon is divided into two types: wood columnar activated carbon (including coconut shell activated carbon) and coal columnar activated carbon. Coal-based columnar activated carbon and wood columnar activated carbon, also known as columnar carbon, are generally made from powdered raw materials and binders through kneading, extrusion molding, and carbonization, activation and other processes. It can also be extruded with powdered activated carbon and binder.

Coal columnar activated carbon:

Coal-based columnar activated carbon is a black cylindrical particle processed by a series of advanced processes using selected high-quality raw coal or anthracite as raw materials. The columnar activated carbon processed by this complex process has a reasonable pore structure and high strength, so it has good adsorption performance and is widely used in the purification of toxic gases, waste gas treatment, industrial and domestic water purification, solvent recovery and so on. The coal-based columnar activated carbon itself has a well-developed pore structure, good adsorption performance, high mechanical strength, and the coal-based columnar activated carbon is easy to regenerate repeatedly, so that the coal-based columnar activated carbon cost is lower.

Columnar activated carbon technical indicators:

Iodine value>1000mg/g

Strength>92%

Specific surface area>850m²/g

Methylene blue value 120-150mg/g

Total pore volume>0.8cm³/g

Residual chlorine adsorption rate ≥ 85%

Filling density 0.35-0.55g/cm³

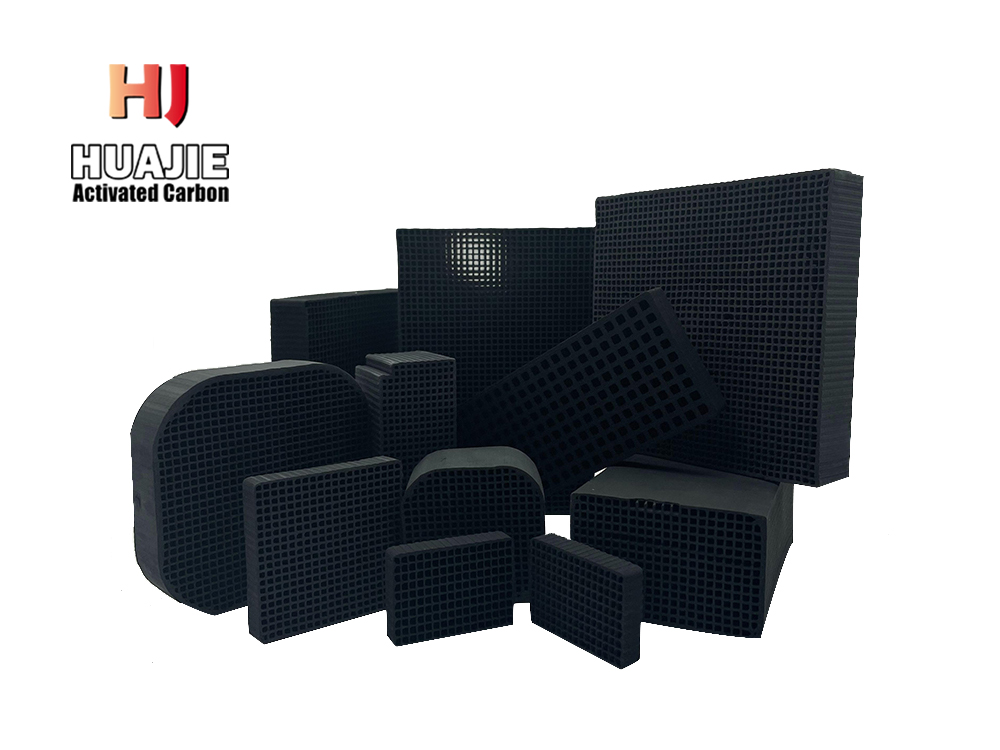

Waterproof and water-resistant honeycomb activated carbon

Waterproof and water-resistant honeycomb activated carbon

wood columnar activated carbon

wood columnar activated carbon

Desulfurization and denitrification columnar activated carbo

Desulfurization and denitrification columnar activated carbo

Solvent recovery columnar activated carbon

Solvent recovery columnar activated carbon

简体中文

简体中文 English

English